Summary. Embark on a journey through the captivating world of 3D printing and scanning. This blog unravels the distinctions between these cutting-edge technologies, shedding light on their unique roles in industries like healthcare and conservation. Discover the pivotal differences that make them indispensable forces in modern innovation.

Technology has evolved at an unprecedented rate in recent years, particularly within the field of 3D scanning and 3D printing.

With each new day comes a brand new development, even more pioneering and unbelievable than the last. From enhancing day-to-day business operations, to transforming the healthcare industry with breakthroughs. Such as the world’s first 3D printed bionic eye, and saving the ocean with a 3D printed reef. The future’s most certainly 3D.

But what’s the difference between 3D scanning and printing? Are they one and the same thing? Or are they two different disciplines? We have specialised in the world of 3D printing and scanning for over a decade. Therefore, we take a look at the processes in more detail, providing you with an insight into the world we live and breathe, day in, day out.

What is 3D scanning?

3D scanning is a fast, efficient process that’s used to collect 3D point cloud data to create three dimensional models. Using specialist software, the 3D data is then quickly processed into a triangle mesh or STL file. After that, we can then use this for a range of applications, including comparison to CAD and 3D printing.

What are the benefits of using it?

It’s fast, flexible, highly accurate, can be used by a wide range of applications and capture large amounts of high quality data.

What’s it used for?

3D scanning involves using non-contact, accurate measuring systems that are used to provide accurate and reliable data. It interfaces with standard 3D CAD packages for fast, effective, quality inspection and analysis.

3D scanning is a particularly useful tool for reverse engineering, prototyping, model-making, pattern and tool-making and 3D printing (which we’ll move on to shortly).

The systems are as diverse as the projects they’re used for. Take our range of 3D scanning systems, for example. They are designed to capture the precise measurements of complex surfaces, geometries and sharp edges across a wide spectrum of objects of all shapes, sizes and textures. In fact, one of the Artec EVA scanners we supply has recently proven pivotal in helping safeguard the future of one of the most endangered species in the world.

In April, an Artec EVA scanner was used to carry out the first ever 3D scan of a rhino’s head. His horn had been ripped out by poachers in South Africa. We were a part of a ground-breaking partnership project involving the charity, Saving the Survivors, ourselves and the University of Nottingham. Watch this short video below to find out more.

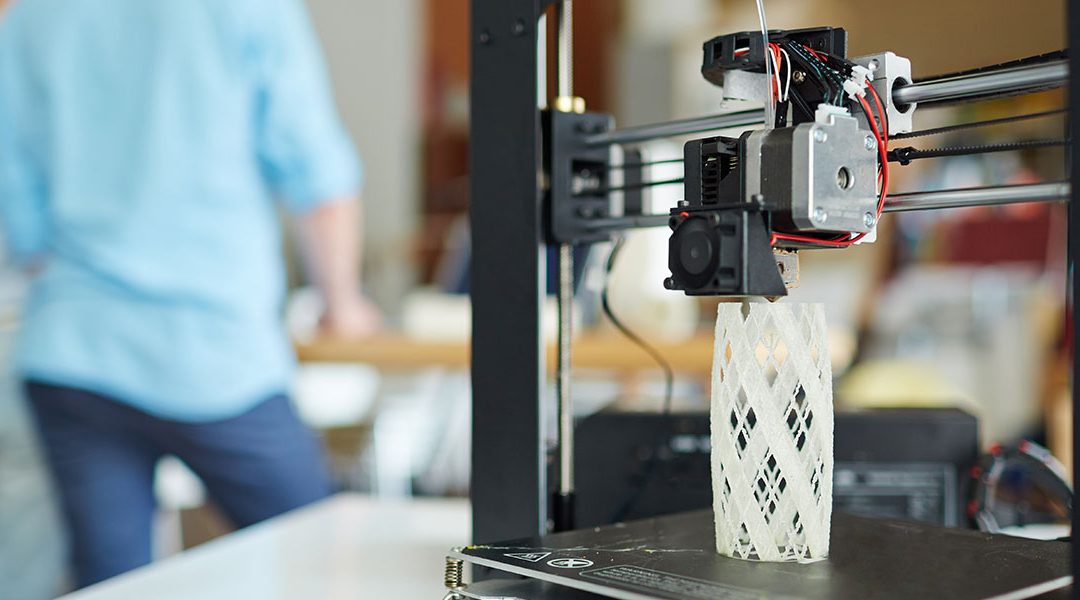

What’s 3D printing?

3D printing is an additive method of manufacturing. STL or CAD files are printed from a digital format to a physical object by laying down successive layers to build up the object. Items can be printed in a variety of materials and shades. It’s also possible to produce working models with moving parts in one go, using the additive manufacturing technique.

What’s it used for?

3D printing is most commonly used as a form of 3D rapid prototyping. Through 3D printing services and 3D rapid prototyping, many companies can verify and change designs more often while spending less money and time doing so. For instance, we can create 3D rapid prototypes within just 24 to 48 hours. This is due to our expertise (and the fact we use only the very best Markforged carbon fibre printers, Stratasys and Ultimaker Polyjet and FDM machines).

So, in the case of our ground-breaking rhino horn project, the valuable scans that were obtained using the Artec scanner are now being transformed into a 3D-printed prosthetic. It’s hoped that these 3D-printed prosthetics will go some way in providing a surgical solution. Helping repair the long-lasting, and often devastating damage, caused by poaching.

What are the benefits of using it?

3D printing enables you to prototype ideas quickly. As well as, bring projects to life and print in a variety of materials and geometries that no other technology can.

3D scanning and 3D printing are two different techniques within the same rapidly-evolving world where virtually anything is possible (with the right technology and know-how) and the opportunities are endless…

Want to find out more about 3D scanning or printing or discuss how it could benefit your business? Contact us on 01527 558282 or info@central-scanning.co.uk.

We 3D Scan, We 3D print, We 3D Care….